Ikeuchi is one of the world’s leading Spraying nozzles and Spray Nozzles Systems Manufacturer. Ikeuchi is the trusted brand in the field of industrial Spraying Nozzles and Spraying system of India. Ikeuchi’s Nozzles produce some of the world’s highest quality for industrial solutions.

Ikeuchi always makes Spraying Nozzles with Customers, as Ikeuchi’s Fog Engineers always give importance on talking directly with customers and solve their problems. Ikeuchi wants to help Indian Manufacturer and Indian companies, to reduce their operating cost and running cost with the improvement of their product quality.

H. Ikeuchi & Co. is a commercial Spraying nozzles manufacturer that contributes to society as a fog engineering services.

"To boldly go where no one has gone before" is the company motto, encouraging the development of creative products such as the world's first ceramic Spraying nozzles.

Spraying nozzles are now used in a variety of fields, such as for washing ,Spray dryer,mechanical components or containers, distributing chemicals, Dust suppression. Preventing static electricity by raising humidity, caused by indoor/outdoor air conditioners.

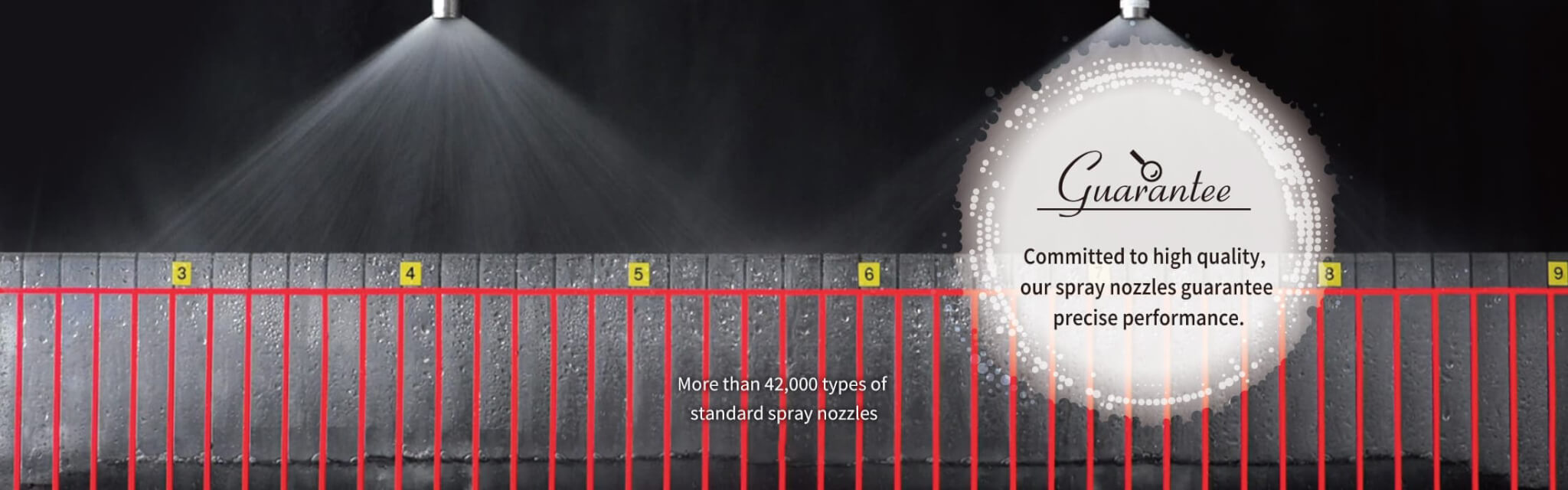

Ikeuchi has provided fog to customers for more than half a century. Throughout Ikeuchi’s history, we have provided more than 42000 different types of Spraying Nozzles to customers, responding to customer preferences & needs with carefully designed fog & Nozzle products.

Ikeuchi always believe to work with customers, by sharing the knowledge of production of spraying nozzles such as Hydraulics (Flat Nozzle, Fullcone Nozzle, Hollowcone Nozzle, and straight jet type), Pneumatic or Air Atomizing Nozzles ,Compressed Air Nozzles & Nozzles related products. Ikeuchi already supplied the Nozzles & Systems to many Indian Customers in textile,Electronics, Steel , Compressed air using industry, Food & Agriculture, Pollution and petrochemical , Automobile and Disinfection Industry. Ikeuchi’s Spraying Nozzles are the solution for indian Customer as per their needs, as Ikeuchi makes Spraying Nozzles accurately and precisely.

Read Less

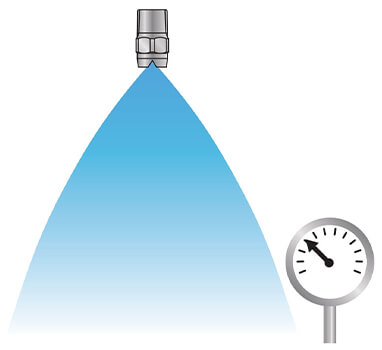

Flow Rate Tolerance

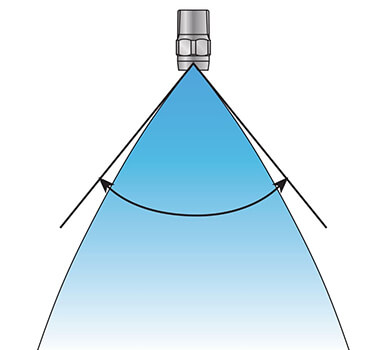

Spray Angle Tolerance

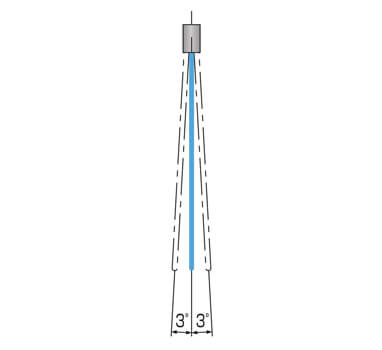

Spray Angle Tolerance for

Solid Stream Nozzles

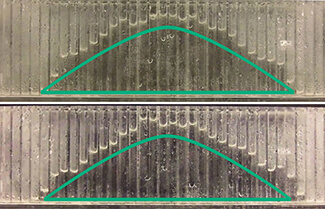

IKEUCHI’s nozzle producing flat

spray pattern with mountain-shaped distribution.

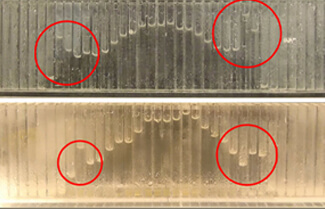

Similar nozzle from another

manufacturer with distorted spray distribution.

In spinning process, dry fog can stably control the humidity in large area. It make prevent napping and threat breakage.

For yarn conditioning room and warping priocess in spinning mil, dry fog improve the process. It can moistening not only surface but deep inside the yarn the cones, make better quality and more high weight.

In weaving process, optimal humidity level reduces almost 20% of thread breakage during weaving, which increases productivity.

In dying process, many user take their time for cleaning. A high impact rotating cleaning nozzle cleans the entire interior of the tank.

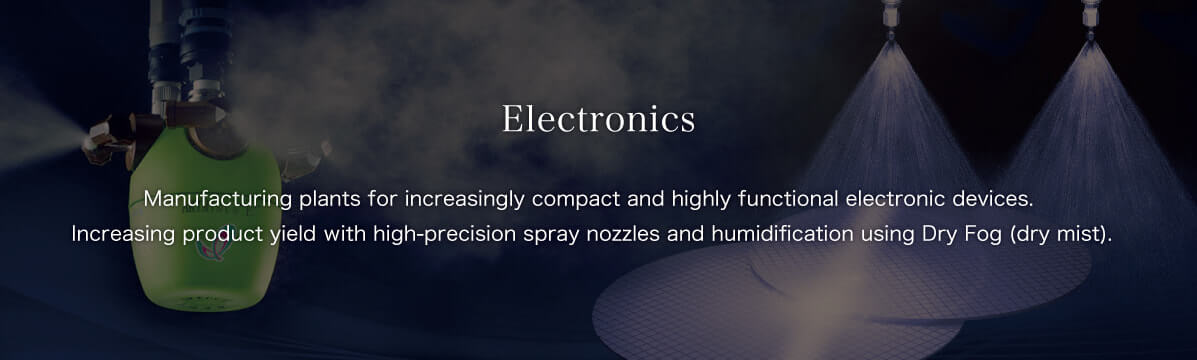

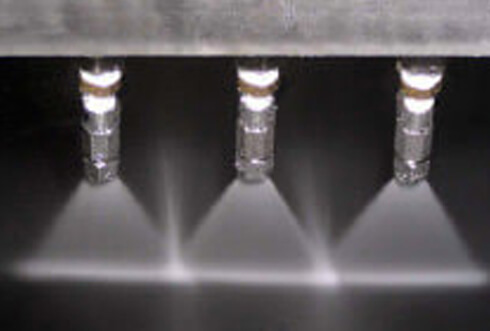

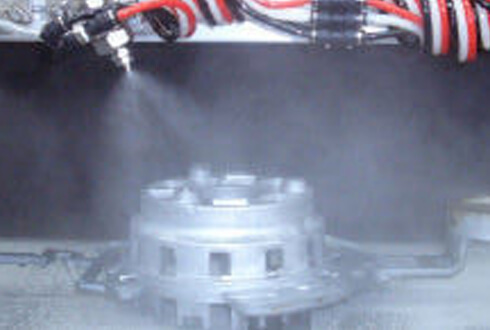

For cleaning of semiconductor wafers, precision cleaning of printed circuit boards, DI water rinsing in wet processes, development, etching, stripping, slurry dispensing and film coating.

Overcoming problems such as electrostatic damage and dust adhesion that cannot be solved by static eliminators (ionizers) only. Reducing pick and place errors, lowering the failure rate and maintaining appropriate humidity in a cleanroom.

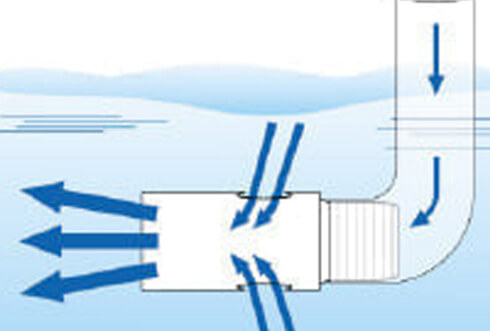

With their compact and lightweight design, ejector nozzles deliver excellent performance for agitation of plating solution, immersion cleaning of printed circuit boards, accelerated etching reaction on products submerged in an etchant, and agitation of a solution in a tank.

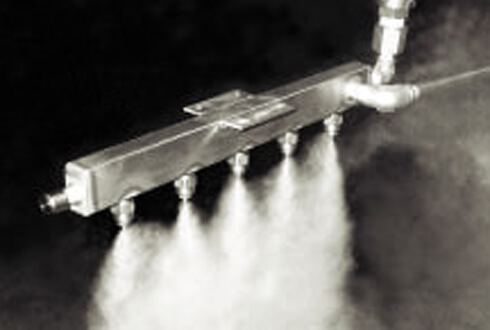

Slit nozzles produce a thin laminar flow of liquid or air of even thickness across the lateral direction, thus reducing chemical solution cost, DI water cost and air cost, and are suitable for smaller, more compact equipment.

Incorporating a noise suppressing design, TAIFUJet air nozzles boost and blow air with an even impact distribution, and are ideal for blowing off water remaining on PCB surfaces.Helps reduce air consumption

Slit nozzles using air, also called air knives, blow air with an even distribution and are suitable for blowing off water remaining on the surfaces of PCBs or flat panels.

Proposing optimal nozzles that cover a wide range of operating flow rate (turndown ratio) to accommodate various casting conditions, along with layouts of those nozzles. Meeting high productivity requirements and accommodating flexible casting of diverse types of steel.

With a unique structure that fully leverages the speed and impact of the water jet, a water-saving, energy-efficient and long-life nozzle minimizes energy loss and overcooling of steel plates.

Cooling refractories without wetting their surfaces. Capable of controlling the cooling speed. Preventing refractories from getting damaged by rapid cooling. Reducing the cooling time of a tundish, an iron runner, a converter and shell of an electric furnace.

BRASHIKan® series, nozzle headers with cleaning function. Automated cleaning of nozzle orifices with built-in brushes and discharge of foreign objects maintain an even spray distribution.

Selecting an appropriate nozzle for various applications and requirements in such processes as continuous galvanizing lines and electrolytic galvanizing lines (CGL & EGL), continuous pickling lines (CPL), continuous annealing lines (CAL) and CCL.

Dust suppression at conveyor hoppers and transfer points. Dust particles adhered to fine fog droplets settle onto the ground. Suppressing dust formation at an exit from a rolling mill or at raw material storage yards.

Incorporating a noise suppressing design, air nozzles boost and blow air with an even impact distribution. It can blowing off water remaining on works surfaces, helps reduce air consumption

For blowing-off in a couch pit on a paper making machine. Preventing paper sticking at a feeder or delivery part. It can suitable for use as an air curtain blocking dust and particles from entering a facility

For blowing away defective products, cooling down food, enriching texture, blowing-off liquid on a process line for drying, pneumatic conveying of powder, agitation in a liquid to prevent precipitation, and making concentration or temperature even.

Slit nozzles using air, also called air knives, blow air with an even distribution and are suitable for blowing off water remaining on the surfaces of PCBs or flat panels.

Combining appropriate nozzles for cleaning various objects such as conveyers, filter cloths, returnable containers, bottoms of bottles or cans, and the insides of pipes. A rotating cleaning nozzle cleans the entire interior of the tank.

Effective disinfection and deodorization using Dry Fog with fine and uniform droplets.

Anti-clogging nozzles, spraying water at low pressure, keeping the water in contact with the product surface for longer, and providing higher heat transfer efficiency, are suitable for pasteurization.

Humidity control in a fermentation room with Dry Fog Humidifier AKIMist®. Measures against static electricity during packaging work.

Conditioning dough surface moisture before baking for better texture after baking.

For an even coating with seasonings, applying a small amount of lubricant or oil, or for automated spray coating with viscous liquids such as chocolate, liquid egg, butter, honey or syrup.

For blowing away defective products, cooling down food, enriching texture, blowing-off liquid on a process line for drying, pneumatic conveying of powder, agitation in a liquid to prevent precipitation, and making concentration or temperature even.

Nozzles producing straight jets for forming and splitting food, or scoring bread and similar food doughs. Warm water spray for defrosting a freezer or food.

Nozzles for cooling flue gas prevents dioxin formation in waste incineration facilities.

Denitrification nozzles for removing NOx in flue gas, and desulfurization nozzles for removing SOx.

Preventing ignition caused by static electricity in Styrofoam manufacturing plants or in processes where organic solvents are used in plastic molding factories. Preventing a product from sticking to each other, electrostatic charge and dust adhesion.

Automated spray for optimizing the amount of release agent or lubricant spray, saving liquid and prolonging mold lifespan. For reducing uneven coating, seizure, galling, formation of gas or other problems.

Automated cleaning of various tanks, containers and conveyors saves labor required for dangerous tasks and troublesome cleaning.

Enhancing cleaning power by spraying detergent in foam form.

Controlling fog quality and amount in accordance with a type of material and its temperature. Efficiently cooling without wetting the object surface. Reducing the cooling time, minimizing the footprint of the cooling process line and lowering the defect rate.

Reducing liquid waste volume to 1/10 to 1/20 by separating and concentrating emulsified oil without using an absorbent or chemical.

Effective for treating liquid waste discharged in various processes.

Automated spray equipment in a compact unit that fits molds of various shapes. Optimized spray flow rate for hard cooling, pinpoint cooling and cost reduction.

Spraying Dry Fog or Semi-Dry Fog® enables cooling of die-cast or cast products, painted products or plastic mold products uniformly, quickly and efficiently without wetting them.

Optimization of amount of release agent or lubricant spray with automated spraying saves liquid and prolongs the lifespan of molds.

Reducing uneven coating, seizure, galling or fume discharge.

Creating a stable humidity environment with Dry Fog Humidification. Reducing adhesion of dust or foreign particles and lowering the defect rate.

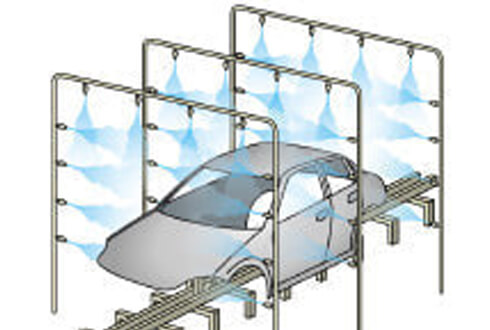

Lineup with high-impact nozzles for removing grime or detergent, and foaming nozzles without using an air compressor.

Lineup with wide-angle nozzles for minimal clogging with large free passage diameter, and high-impact narrow-angle nozzles. Offering labor savings with an automated spray system.

2,500,000,000 fog droplets per second.The Amazing Fog will provide your clients with new surprises and the usual ease.

Unit sprays disinfectant or deodorizer in the form of Dry Fog, a very fine fog. Backup type for use in any place with the batteries and the chemical tank integrated. Backpack type for use in any place.Capable of spraying for approx. 40 minutes with batteries fully recharged. World patent pending.

Portable dry fog humidifier set with energy-saving humidifiers producing Dry Fog. AE-T set includes Dry Fog humidifier AKIMist “E”, stand unit, and satainless made water pressure tank, pressure control. Possible to use immediately by simply connecting the air supply.

A simple and easy unit spraying in a fine fog.

Connect an air compressor for immediate use anywhere.